Feature

Reducing the carbon footprint of baggage handling

As airports strive to reduce their carbon footprint, all operations are under scrutiny – including baggage handling. Keri Allan highlights some examples of new technology improving baggage handling operations for airports.

Main video supplied by Damir Galeev/Creatas Video+ / Getty Images Plus via Getty Images

Baggage handling might not be the first thing that comes to mind when talking about airport sustainability, but that’s starting to change. Conveyor belts, baggage carts, and other equipment used for luggage handling within airports all consume energy, making considerable contributions to an airport’s carbon footprint.

However, there are new solutions being applied to help reduce the environmental impact of baggage handling operations. From energy-saving conveyor systems to hydrogen-powered tugs and autonomous vehicles, airports are finding clever new ways to make baggage operations greener.

It’s all about reducing emissions, cutting energy use, and keeping things running smoothly behind the scenes, as these examples show.

Select the location to view a case study

1

Pitsburgh International Airport: more energy-efficient baggage systems

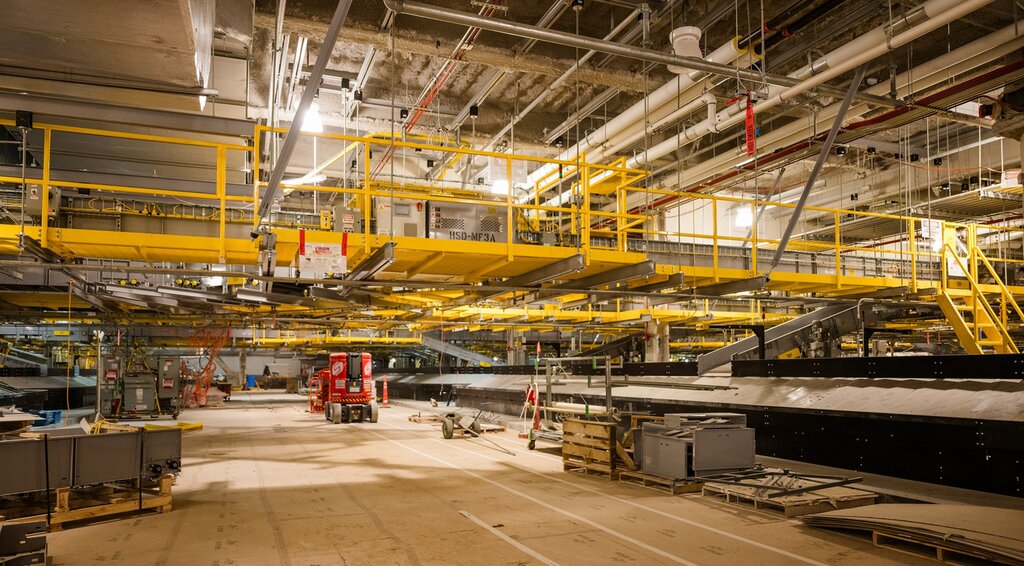

As part of Pittsburgh International (PIT) Airport’s terminal modernisation program, a new baggage system has been designed to minimise energy consumption and maintenance needs.

The new terminal is scheduled to open later this year, with its baggage system designed to be more energy-efficient, cheaper to operate and easier to maintain. The airport is currently operating two baggage systems – the North system used by United and Southwest Airlines, and the South system used by the remaining airlines.

Today’s PIT was built in the early 1990s as part of the US Airways hub design, with a baggage network spanning approximately eight miles of conveyor belts running between the landside terminal and the airside terminal via an underground tram. In 2004, US Airways de-hubbed, and today approximately 98% of the nearly 10 million passengers passing through the airport either begin or end their travel itinerary in Pittsburgh. These changes led to the terminal modernisation project currently underway.

Sustainability and energy efficiency were central goals built into the design brief for the new baggage system, which is less than three miles in length, and is 40%-60% more energy efficient than its predecessor.

These permanent magnet motors are typically 2%-10% more efficient than traditional induction motors, especially under variable loads.

The new system uses high-efficiency permanent magnet motors, which were chosen specifically for their lower heat output, reduced noise and better energy conversion.

“These permanent magnet motors are typically 2%-10% more efficient than traditional induction motors, especially under variable loads. This leads to lower energy consumption, which is critical for 24/7 systems like baggage conveyors and sorting arms,” says Rusty Hottenfeller, director, facility maintenance and airline service at Allegheny County Airport Authority.

“They also generate less waste heat, which reduces the burden on HVAC systems and minimises the need for motor cooling – important in confined spaces like baggage halls – and provide strong torque at low speeds, which is ideal for precision control in systems that start and stop frequently. This means better performance in acceleration, deceleration, and smooth handling of delicate luggage.

“A more compact design also cuts down on the distance travelled by the tugs and carts by 50% or more,” Hottenfeller adds.

The new baggage system was also integrated into the larger Leadership in Energy and Environmental Design (LEED)-focused terminal plan. The entire terminal, including baggage operations, is powered by PIT’s microgrid, which runs on 10,000 solar panels and natural gas. The HVAC and lighting systems in baggage areas are energy-optimised and automated for occupancy.

The new baggage handling system during construction. Credit: Allegheny County Airport Authority

2

Exeter Airport: hydrogen-powered baggage tractors

As part of a demonstration to show how hydrogen can support the decarbonisation of airport ground operations, Exeter Airport in the UK recently trialled three pieces of hydrogen gas-powered equipment, including a baggage tractor.

“We trialled three pieces of hydrogen (H2) equipment – an aircraft tow tug, a baggage tractor, and a hybrid GPU. These categories of ground support equipment were identified in an earlier study as contributing a significant share of emissions at the airport. Hence, they represented good candidates for decarbonising,” notes Dr Thomas Budd, associate professor of airport decarbonisation at the Centre for Air Transport Management, Cranfield University.

The trial was delivered by a partnership including Exeter Airport, Cranfield University, and Boeing, and was supported by the UK Civil Aviation Authority’s Hydrogen Challenge programme. The equipment each had different H2 configurations, so that the three main pathways to employing H2 for GSE could be showcased, which, in the case of the baggage tractor, was an H2 fuel cell.

The performance of the three vehicles in terms of towing capacity, range and power is comparable with their diesel equivalents, so no compromises were made in terms of operational performance. Furthermore, if rolled out permanently, the consortium has estimated that these would save around 20 tonnes of CO2 annually.

As part of phase two of the CAA’s Hydrogen Challenge Sandbox programme, the consortium is currently exploring additional applications and uses for H2 at the airport, including higher volume storage and use under different operating conditions.

“We’re keen to reinforce that H2 for GSE serves a dual purpose; both to explore the potential for H2 to support decarbonisation of ground operations in the short term and develop learning to support the case for handling hydrogen for aircraft in the future,” Budd notes.

“It’s also important to remember that H2 is not seeking to replace electric GSE. It represents an additional pathway that, in some cases, can provide operational benefits compared with electrification.”

The hydrogen gas-powered ground support equipment trialled at the airport. Credit: Exeter Airport

3

Amsterdam Airport Schiphol: autonomous baggage handling vehicles

Amsterdam Airport Schiphol is currently trialling an electric, autonomous vehicle for baggage handling. This includes autonomous vehicle movements on the airside and in baggage halls, as well as autonomously handling AKE and AKH-sized baggage containers, picking and dropping them off from various types of equipment or interfaces.

The pilot, a collaboration between KLM and Aurrigo, runs until the end of 2025 and is intended to eventually become part of regular operations. The autonomous vehicle takes the cases of passengers with a long transfer time from the plane to a temporary storage location. At the right time, the vehicle then takes the m from there to the baggage hall, where it goes into the system for further handling.

Currently, the airport is working towards new phases of the project that will test the capabilities of the Aurrigo vehicle to autonomously load baggage containers on and off the various types of equipment, such as highloaders or roller decks.

While the trial doesn’t specifically focus on sustainability gains, the airport believes autonomous vehicles will minimise the number of movements in the future, helping to optimise routes, save energy, and reduce pressure on airside roads.

“This supports Schiphol’s broader strategy of reducing operational emissions and improving airside efficiency,” says Jeroen Kamp, innovation lead for future baggage, Amsterdam Airport Schiphol.

The airport has also been looking into other ways to improve sustainability across baggage handling operations.

“With the renovation of baggage halls and retrofitting of new technology as a replacement of current infrastructure, we’re looking at more energy-efficient technologies available to do the same job or function,” notes Kamp.

The new electric, autonomous vehicle for baggage handling being trialled at Schiphol. Credit: Aurrigo